Valfleuri and its history

1922

Created in Guebwiller (Haut-Rhin) in a small bakery workshop by Frédéric Kuentz (grandfather of the current managers), the family business Valfleuri has since continued to develop.

40’s

Following the death of the founder, his wife Marguerite, mother of 5 children, took up the torch and ran the workshop then composed of 8 people.

1949

At the age of 16, Frédéric Kuentz (son), comes to support his mother and undertakes to modernize the company. He chose to invest in a machine for the continuous production of pasta and expanded Valfleuri by moving to a former textile factory in Guebwiller. He was joined in 1956 by his brother Denis.

70’s

In order to counter growing competition, the Kuentz brothers stand out by producing pasta very rich in eggs, inspired by an Alsatian recipe dating from the 17th century: this is the birth of the “Pâtes d’Alsace with 7 fresh eggs / kg of durum wheat.

Noodles are rolled up in the form of nests and sold in transparent confectioner’s bags, closed with a golden clip. The success exceeded the expectations of the two brothers, and the recipe for Pâtes d’Alsace was adopted by the majority of Alsatian manufacturers.

The company is expanding again by moving to a former textile factory in Linthal (Haut-Rhin): 45 people work there for 12 tonnes of pasta produced daily.

80’s

With the success of the Pâtes d’Alsace and the boom in mass distribution helping, Valfleuri built a 10,000 m² factory in Wittenheim (Haut-Rhin). From then on, the company devoted itself to the manufacture of “Pasta d’Alsace with 7 fresh eggs” and to marketing throughout France.

Between 1986 and 1990, Valfleuri modernized, expanded and increased its production capacity, the latter increasing from 6,000 T to 14,000 T per year.

Valfleuri becomes the European leader in the production of Alsatian pasta with 7 fresh eggs

90’s

Arrival of the 3rd generation who gradually takes over the management of the company. Under his leadership, significant progress was made and the plant was expanded. Valfleuri is reorganizing, consolidating its know-how and developing an internal laboratory for physico-chemical and microbiological analyses.

The company is committed to a quality approach and in 1994 became the first French pasta manufacturer to obtain ISO 9002 certification.

The expansion of the site continued in the 1990s with the construction of a 4,000 m2 extension and the modernization of the manufacturing and packaging workshops.

2000’s

Valfleuri is embarking on a strategic shift by developing new, original recipes and strengthening the legitimacy of Pâtes d’Alsace while changing the company’s logo and revamping the packaging.

In partnership with other Alsatian manufacturers, Valfleuri initiated a PGI (Protected Geographical Identification) certification process for Alsatian pasta, obtained in 2005.

2010’s

From 2010, the fresh eggs used in the composition of Pâtes d’Alsace Valfleuri all come from free-range hens in France.

Pat’atouilles, a unique pasta very rich in vegetables, was awarded the 2012 ARIA Innovation Trophy.

The company is continuing to expand, fitting out a new 11,000 m2 hall for storing and shipping pasta.

At 83, Frédéric Kuentz hands over the management of the company to his son Matthieu Kuentz CEO and his daughter Sabine Kuentz Marienne Managing Director.

The products are redesigned, the French origin of the ingredients is favoured, a new local durum wheat sector is created and the packaging of the Pâtes d’Alsace is restyled for this occasion.

In recognition of its long-standing commitment to a CSR (Corporate Social Responsibility) approach, Valfleuri obtained, in October 2018, the PME+ label “for a more committed world”, followed by the Alsace Excellence label.

2020’s

Valfleuri continues to develop its durum wheat channel and new products:

2020 launch of 3 innovative ranges of organic pasta, rich in vegetables or legumes, quick cooking.

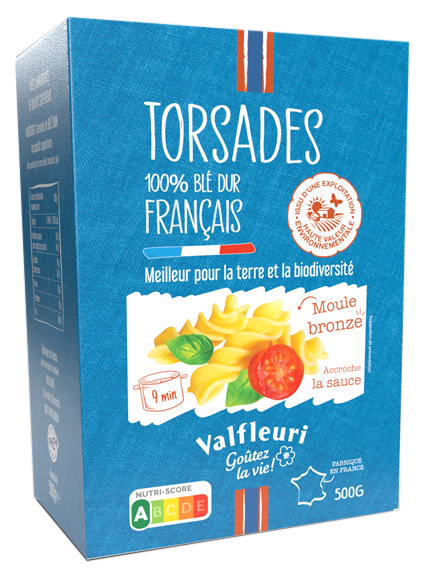

2021 launch of an unprecedented range of 100% durum wheat pasta with the HEV label, based on the creation of a French durum wheat channel from farms with High Environmental Value.